BRAND ORIGIN

In recent years, many new brands have emerged in many countries other than Japan. Automatic detection and more tolerant elastic technology for swing speed are also becoming popular. We believe this is a correct direction to design a shaft. There will be many different swing speeds generated on the same person in different seasons, different courses, and different strategies. Therefore, if the old-fashioned fitting thinking of selecting specifications by measuring and customizing is used, it will lead to the fact that each person may need many different specs of shafts to face different climates, different holes, different physical conditions, and different swings. And this is not a good thing for golfers and may even disrupt their swing rhythm.

Too high trajectory、Durability、Material、Difficult to Control Ball Flight、Energy Dispersion、Cost constraints.

The inception of Future Flex

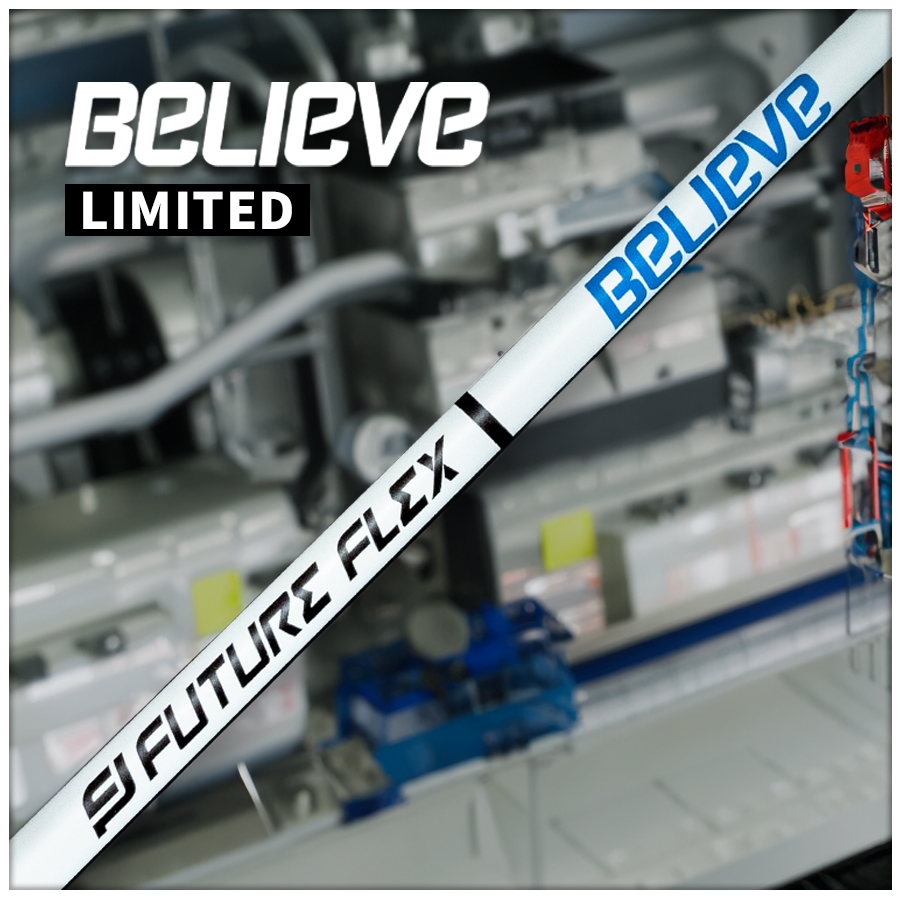

Due to the limitations of current automatic detection technology for golf club shafts, our brand, Future Flex, was created to address these issues and provide a better experience for golfers.Founded in the UK, with a design team consisting of professionals from around the world, dedicated to developing cross-generational technology for golf shafts.

Our shafts not only require advanced automatic detection technology but also possess the following outstanding qualities:

- Durability

- More concentrated and faster energy transmission

- Exceptional ball flight strength

- Excellent ball control ability

- The use of the best possible materials regardless of cost

With these ideal qualities in mind, we spent over two years on design and development, and finally, Future Flex was born! Our innovative lineup includes:

You Could Described They Are The Shafts From The Future

Common Issues

v.s

Our Optimization

TOO HIGH TRAJECTORY

Due to the elasticity of the shaft, it is difficult to apply force during the downswing process, resulting in a generally high ball trajectory.

v.s

STABLE AND POWERFUL TRAJECTORY

The shaft is designed to create a stable and powerful ball trajectory based on the player’s swing speed and force.

DURABILITY

Since the shaft is designed with very soft elasticity, it is prone to elasticity fatigue, resulting in durability issues. Even when paired with a heavier clubhead, it may cause directional instability.

v.s

DURABILITY MEETS PRECISION

The product adapts the appropriate flexibility and strength for each player’s individual swing, rather than relying solely on the bending and rebound of the shaft itself. This reduces unnecessary forces and counterforces, enhancing both trajectory stability and product durability.

DIFFICULT TO CONTROL BALL FLIGHT

For advanced players who want to hit different high, low, draw, and fade ball trajectories, it is difficult to achieve precise control with this type of shaft. The main reason is still the slow energy transfer issue.

v.s

EXCEPTIONAL BALL CONTROL SENSATION

We’ve addressed the issue of energy transfer between the golfer and the shaft. Advanced players using our products will discover the ability to freely control various trajectories, including high, low, left bend, and right bend.

COST CONSTRAINTS

As mentioned above, if this type of shaft with automatic detection wants to be made with medium or high-tonnage carbon, the design, development, and material costs will be very high, and the selling price will be extremely expensive.

v.s

CONTROLLABLE COSTS

Our product technology features automatic detection capabilities, and because it is exclusively developed and independently produced, costs can be controlled within an optimal range.

ENERGY TRANSFER AND DISCRETE

The acceleration of this type of shaft usually comes from the elasticity rebound, but the force (energy) applied to the shaft during the downswing process gradually diminishes. Therefore, only the whipping action can effectively increase the swing speed. If force is applied during the downswing process, the energy transfer may be lost due to dispersion, and the shaft’s softness may cause directional instability.

v.s

EFFICIENT TRANSFER OF ENERGY

Due to the product’s built-in automatic detection feature, it doesn’t solely rely on the flexibility of the shaft to generate hitting force. The automatic detection adapts to the player’s swing speed and strength, optimizing the transfer of force to minimize loss during the transmission of power.

MATERIAL LIMITATIONS

Since soft elasticity is used to increase rebound, the materials used in this type of shaft cannot use high-tonnage carbon, which is also one of the important reasons for the previous shortcomings.

v.s

COMBINATION OF MATERIALS AND TECHNOLOGY

Our product relies on the synergy of automatic detection technology and materials, reducing the various drawbacks associated with relying solely on shaft flexibility to produce hitting effects.